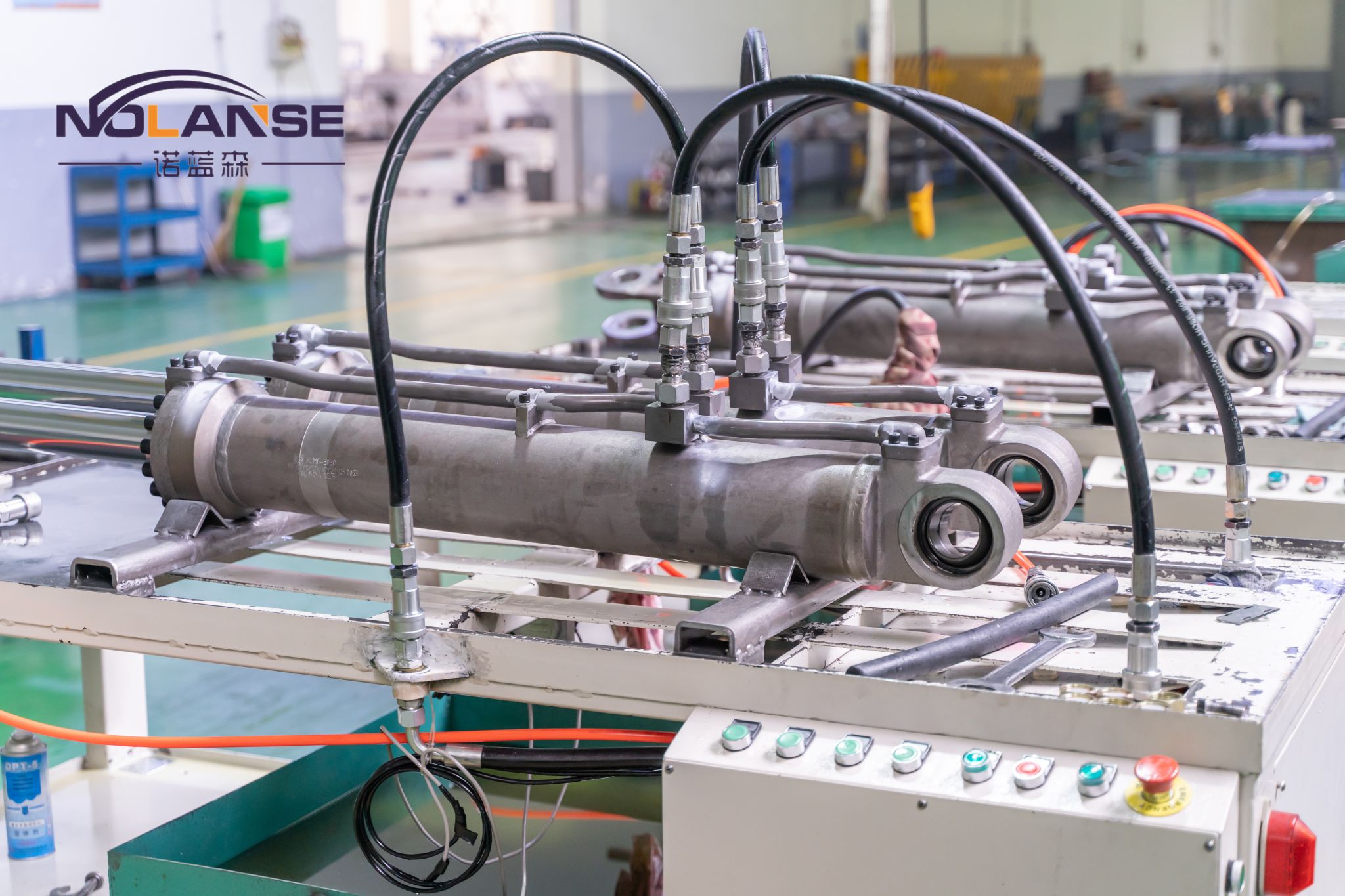

Precautions for Testing Hydraulic Cylinders

When testing hydraulic cylinders, there are several key points to note:

1Safety precautions: Before conducting the test, ensure that you have taken appropriate safety measures. This may include wearing personal protective equipment, ensuring the testing area is clear of other personnel, and familiarizing yourself with the correct emergency procedures.

2.Pressure measurement: When testing a hydraulic cylinder, it is necessary to measure the pressure. Make sure you use the appropriate pressure gauge and measuring equipment and ensure their accuracy and suitable range.

3.Leakage check: Prior to testing, inspect the hydraulic cylinder for any leakage issues. Check for any obvious fluid leaks in the cylinder and connection points and ensure that seals and pipe connections are tight.

4.Stroke limitations: Understand the stroke limitations of the hydraulic cylinder. Do not exceed the maximum stroke range of the cylinder to avoid damaging the cylinder or other equipment.

5.Clean maintenance: Ensure that the hydraulic cylinder and related equipment are kept clean.Regularly clean the hydraulic cylinder to remove accumulated dirt and impurities to ensure its proper functioning and longevity.

6.Specifications and guidelines: Follow the testing specifications and guidelines provided by the manufacturer of the hydraulic cylinder. These specifications and guidelines typically include detailed information about the testing procedures, safety precautions, and maintenance recommendations.

Please note that these are just suggestions, and specific testing requirements may vary depending on the type and application of the hydraulic cylinder. It is advisable to refer to relevant technical documentation or consult professionals for accurate guidance before conducting the test.